Learning Objective

1. Understand DoD project specification related to blast for roof trusses

2. Understand main concepts of design to mitigate effects of blast on roof trusses

3. Discuss engineering role during bidding phase and design phase

The Unified Facilities Criteria UFC 4-010-01 was created with the overarching goal of minimizing the likelihood of mass casualties from terrorist attacks against DoD personnel inside buildings routinely occupied. The applicability of UFC 4-010-01, unless adequate standoff can be provided, is to all DoD inhabited buildings, billeting, and high occupancy family housing, and to all DoD expeditionary and temporary structures. Existing buildings that cannot meet required standoff distance are required to meet the requirements set forth by UFC 4-010-01 when the building undergoes a renovation, modification, repair, or restoration that exceeds 50% of the replacement cost of the building.

UFC 4-010-01 provides “conventional construction standoff distances” that when achieved would permit building components to be built with minimum additional construction cost for blast protection. Among these building components are wood stud walls, steel stud walls, concrete and masonry walls, concrete roofs and metal roofs. However, cold-formed steel (CFS) truss roofs are not included in the permitted components due to the fact that no field testing or detailed dynamic analysis have been performed to define their appropriate construction standoff distances. As a result, CFS roof trusses included in DoD projects must go through an additional design step to dynamically analyze the trusses against the blast pressure per the site standoff distance, and provide truss hardening if needed to mitigate blast effects. This design task is often delegated from the project’s Engineer of Record to the truss manufacturer and their structural engineer.

With the knowledge and experience FDR Engineers has acquired in dynamic analysis, we were able to provide truss manufacturers with effective blast analysis service for CFS roof trusses. Samples of projects we recently worked on are:

• Soldier Family Critical Care Facility, Fort Drum, NY

• Cannon AFB Medical-Dental Clinic Replacement, Cannon AFB, NM

• US Coast Guard Station, Sabine Pass, TX

• Fort Gordon Admin Building, Fort Gordon, GA

• KC-46A Pipeline Student Dormitory, McConnell AFB, KS

• KC-46A 1-Bay and 2-Bay Hangers, McConnell AFB, KS

• FY13 Battalion Headquarters, Fort Leonard Wood, MO

A project’s blast analysis typically starts with reading the project’s specification and the blast design criteria. In some cases the blast criteria is provided in the form of a blast source charge weight and a standoff distance to the edge of the building. In other cases a peak blast pressure and a peak impulse are provided to be used directly in the dynamic analysis. Attention should be given to the design criteria to see whether a negative blast pressure phase is specified. The negative phase analysis is important for truss design details such as locating bracing on the truss bottom chord and anchorage of truss support points.

As a general design strategy for CFS roof trusses against blast, the roof system is best to absorb blast energy through yielding and significant plastic deformation, but should not fail. In addition, the members of the truss must reach their ultimate load points before their end connections.

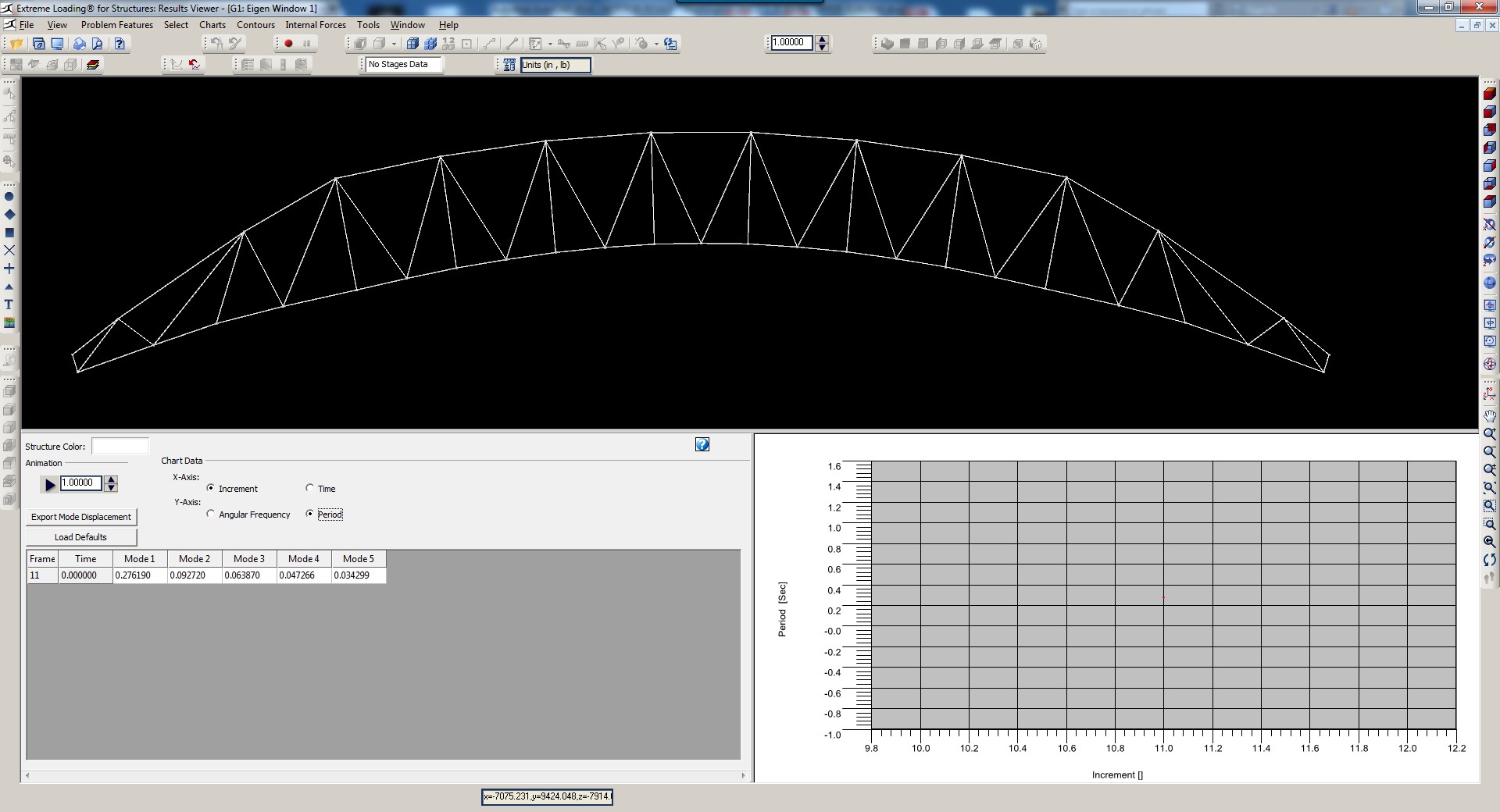

FDR’s project’s plan is to group CFS trusses by geometry, span and dead load, and dynamically analyze trusses representing the groups. Depending on the project’s specification and blast design criteria, the blast analyses either targets the calculation of equivalent static blast pressures using the response of an elastic single-degree-of-freedom (SDOF) system, or develop detailed analysis models and perform SDOF or two-dimensional (2D) dynamic analysis to obtain dynamic deformation and equivalent forces. In either case, the process is iterative since truss flexural behavior is a function of its stiffness, mass and dynamic properties, and may require two to three iterations of analysis and design until convergence occurs.

FDR Engineers offers support service to their clients of truss manufacturers during the project bidding phase. This is an important task in order to help the manufacturer identify the blast design information from the construction documents and properly size and price the truss system while taking the blast criteria into consideration. FDR Engineers offers recommendations to the truss manufacturers during the bidding phase on member sizes, load combinations, and how to determine bracing points on the bottom chords and web members of the trusses in order to achieve the most optimized design.

Recent Comments